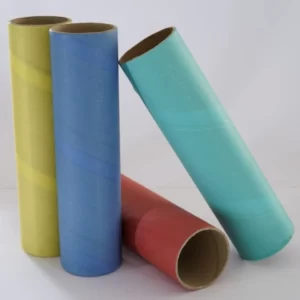

Cardboard yarn cones are made out of cardboard and their main and important use in the textile industry is for winding and holding yarn.

Cardboard yarn cones 4° 20´, 5° 57´

Types of surface finishing: Velvet finish

Specs

| Final product |

Top inner diameter (millimeters) |

Base inner diameter (millimeters) |

Weight (grams) |

Length (millimeters) |

angle |

| Sanding the outer surface / Lip turning / Hardened opening / Slotted / Yarn holding groove / Various designs and prints |

27mm-28mm |

58mm |

+40gr |

170mm |

4°20´ |

| Sanding the outer surface / Lip turning / Hardened opening / Slotted / Yarn holding groove / Various designs and prints |

27mm |

67mm-68.5mm |

+40gr |

173mm |

5°57´ |

Description

Cardboard yarn cones are made out of cardboard and their main and important use in the textile industry is for winding and holding yarn. This product is designed in such a way that it can keep the thread regularly on its body and make it easier to use. Strong and durable cardboard is used for the preparation and production of the cardboard yarn cones so that the cone can withstand when the thread is wound around it. To use this product, they usually move the thread from the top of the cone to its base. This process ensures that the thread stays in place and prevents it from tangling or unraveling. The use of cardboard cones in the textile industry has several advantages, such as the process of spinning yarn, and storing and transporting it is easier and more organized. In addition, its conical shape and cardboard material help to stack them easily and store them in boxes. Cardboard cones can be recycled and reused, so they are considered a green and environmentally friendly option, which is very important.