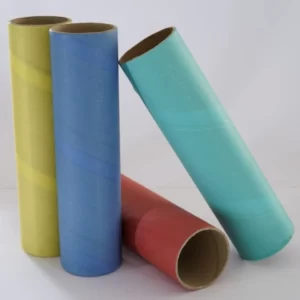

This type of tube is known as a continuous and bulky yarn cardboard tube. A special type of cardboard tube used in the textile industry for winding and storing BCF yarn.

- Custom orders can be placed based on specific customer requests or needs.

Product Information

| Application |

Bottom Diameter (mm) |

Weight (g) |

Length (mm) |

| Spinning |

72mm-75mm |

130g-230g |

28mm-29mm |

Description

This type of tube is known as a continuous filament bulky cardboard tube. A specific type of cardboard tube used in the textile industry for winding and storing BCF yarn. BCF yarn is known for its high bulk and coverage factor, making it suitable for carpet piles, knitting yarn, floor coverings, rugs, and upholstery. Therefore, these tubes are designed and manufactured to match the unique characteristics of BCF yarn.

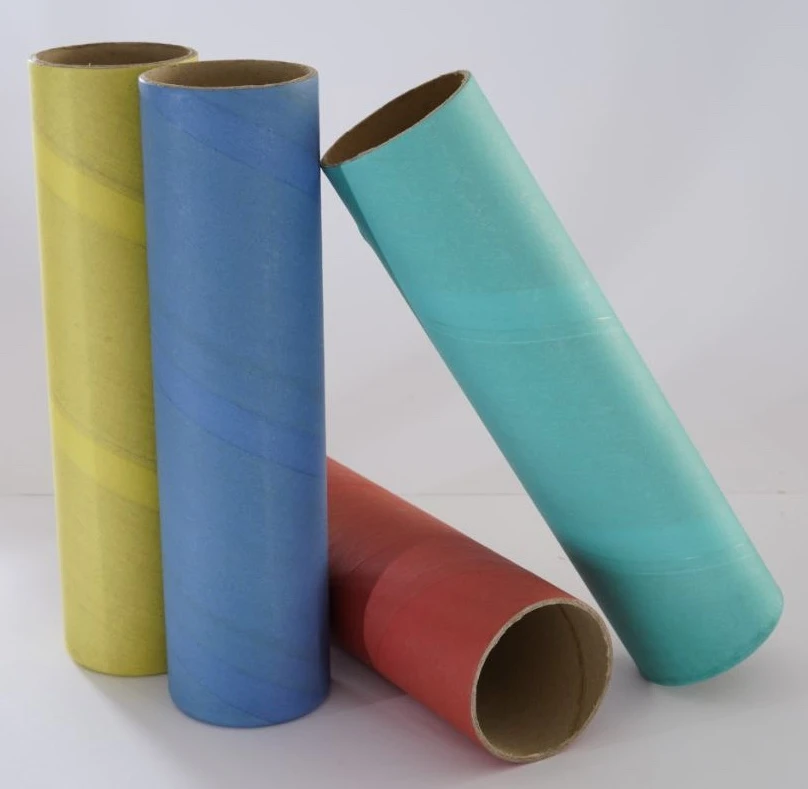

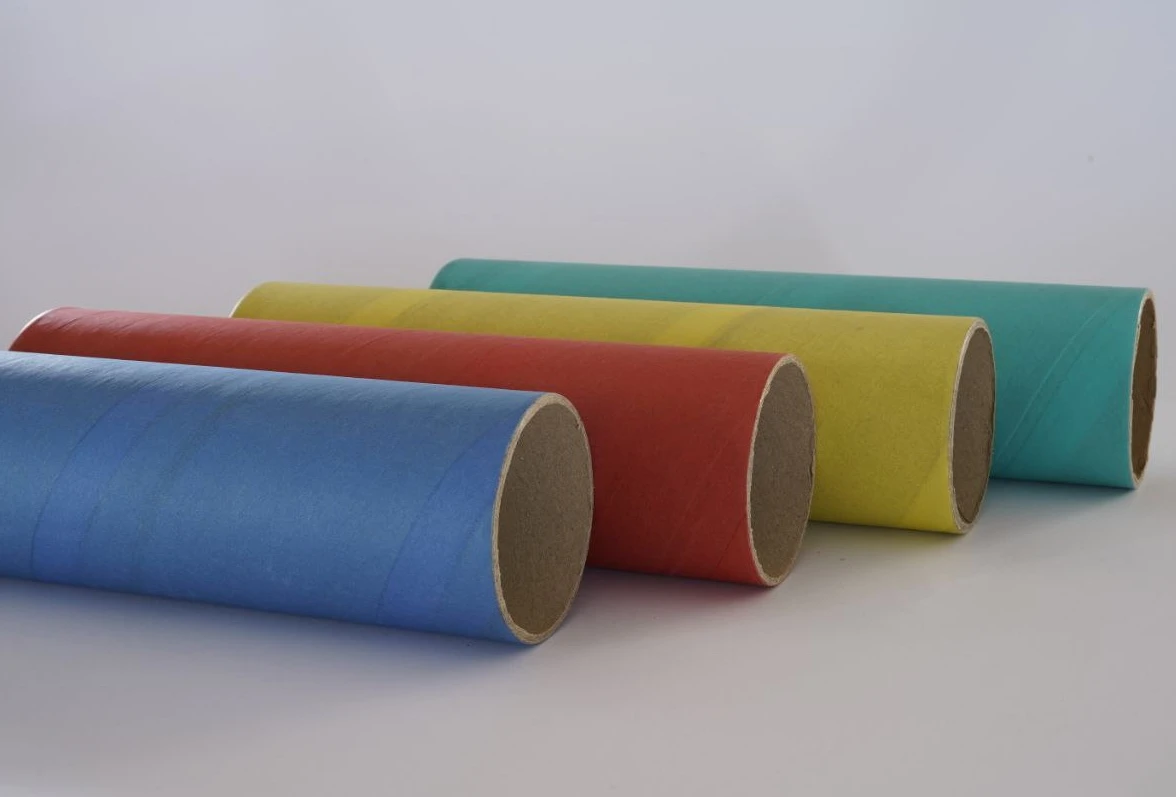

These tubes are typically larger and thicker in size compared to other types of cardboard tubes. The primary reason for this is that BCF yarn is often produced in bulk quantities. For this reason, the larger size of these tubes allows for winding more yarn onto the tube.

BCF tubes are made from high-quality and durable cardboard materials to ensure their ability to support the heavy weight of BCF yarn. This product is specifically designed and manufactured to withstand the tension and pressure exerted by the yarn during the winding and transportation process.

During the production process of this product, special grooves or slots may be created on the top surface to ensure that the yarn adheres firmly to the tube during the winding process. This helps prevent the yarn from slipping or unraveling during winding.

One of the advantages of using BCF cardboard tubes in the textile industry is the increased capacity for uninterrupted BCF yarn production. The larger size of these tubes allows for winding more yarn onto each tube, reducing the total number of tubes required. Furthermore, by securely holding the yarn on these tubes, optimal storage conditions are ensured, leading to reduced waste and potential defects in the final product. Finally, the cardboard construction of this product allows for recycling, repurposing, and reuse, which aligns with the environmental impact of reducing waste disposal.